STARCH (NEŠĀSTE)

The general term for starch, nešāste, is mentioned in numerous treatises without specifying whether it is rice or wheat starch. It is highly likely that the term is used for wheat starch, as Biruni specifically associates it with wheat and notes that the origin of the term "našāsta" or "našā" (as its abbreviation) is Persian.

Recipes:

In three treatises—Ṣerāt al-Ṣoṭur (920 A.H./1514 A.D.), Favāyed al-ḵoṭuṭ (995 A.H./1587 A.D.), and Resāle dar Bayān-e Ḵaṭṭ va Morakkab va Kāḡaḏ va Sāḵtan-e Ranghā (19th century)—all three explicitly recommend mixing eremurus paste (seriš) with the starch paste, following the same approach as described in the poem. The esteemed calligrapher Solṭān Ali Mašhadi, in Ṣerāt al-Ṣoṭur (920 A.H./1514 A.D.), whose recipe is also replicated in Resāleh dar Bayān-e Ḵaṭṭ va Morakkab va Kāḡaḏ va Sāḵtan-e Ranghā (19th century) by an anonymous author, dedicates several couplets in his treatise to the mixture of starch and eremurus glue, emphasizing the glazing of paper by hand shown here:

در باب آهار ساختن و کاغذ آهار کردن

ساز آهار از نشاسته کن بشنو این زپیر پخته سخن

اولاً کن خمیر و آب بریز پس بجوشش دمی به آتش تیز

پس لعاب سرش به او کن ضم صاف سازش نه نرم و نه محکم

رو به کاغذ بمال و سعی نمای تا که کاغذ نیوفتد از جای

کاغذِ خویش چون دهی آهار مال آبی به روی او زنهار

In the art of sizing, let knowledge be your guide,

Craft the size from starch, wisdom can't hide.

First, a paste forms, water joins the ballet,

On the fire it boils, a brief fiery display.

Eremurus paste whispers, blend it with grace,

Strain to perfection, a delicate embrace.

On paper it's spread, in its place it stays,

Ensuring no movement, a skillful ballet.

When size meets paper, in careful layers,

Moisten with water, as skill declares.

Mohammad Ibn-e Dust Mohammad Boḵāri in Favāyed al-ḵoṭuṭ (995 A.H./1587 A.D) has written the same recipe mentioned above with some small modifications in the last two couplets as follows:

هم به کاغذ بمال و سعی نمای تا که کاغذ بدو [شود بی لای]

کاغذ خویش چون دهی آهار مال آبی بروی او هموار

On paper, spread with a skilled display,

No wrinkles formed, as it found its way.

When sizing meets paper, a careful affair,

Moisten with water, make it smooth and fair.

Moreover, Mohammad Ibn-e Dust Mohammad Boḵāri, in Favāyed al-ḵoṭuṭ (995 A.H./1587 A.D), also described the same recipes, advising the mixture of sizing using starch and eremurus paste in prose form. The recipe reads as follows:

و دیگر طریق آهار پختن و مالیدن بر کاغذ، آن است که نشاستهٔ پاکیزه بگیر و خمیر کن و آب بریز و صاف بکن و در دیگ بینداز که چرب نباشد و بجوشان و لعاب سرش را بدو ضم کن و باز صاف ساز امّا نه تُنک باید پخت و نه غلیظ، پس متوسط الحال باید. بعد از آن به کاغذ بمال بعد از مالیدن به کاغذ، آبی بر او نیز بمال که هموار و به یک منوال می آید و خوشْ قلم می شود

To prepare a size and apply it on paper, take some clean starch and make a paste. Add water, then strain and pour it into an oil-free pot to boil. After that, add some eremurus paste (seriš) to thin the starch and strain it again. The cooking process should neither make the size too thin nor too thick; it should be medium. Then apply it on paper. After applying the size, add some water to make the surface homogeneous and smooth, suitable for writing.

Experiment:

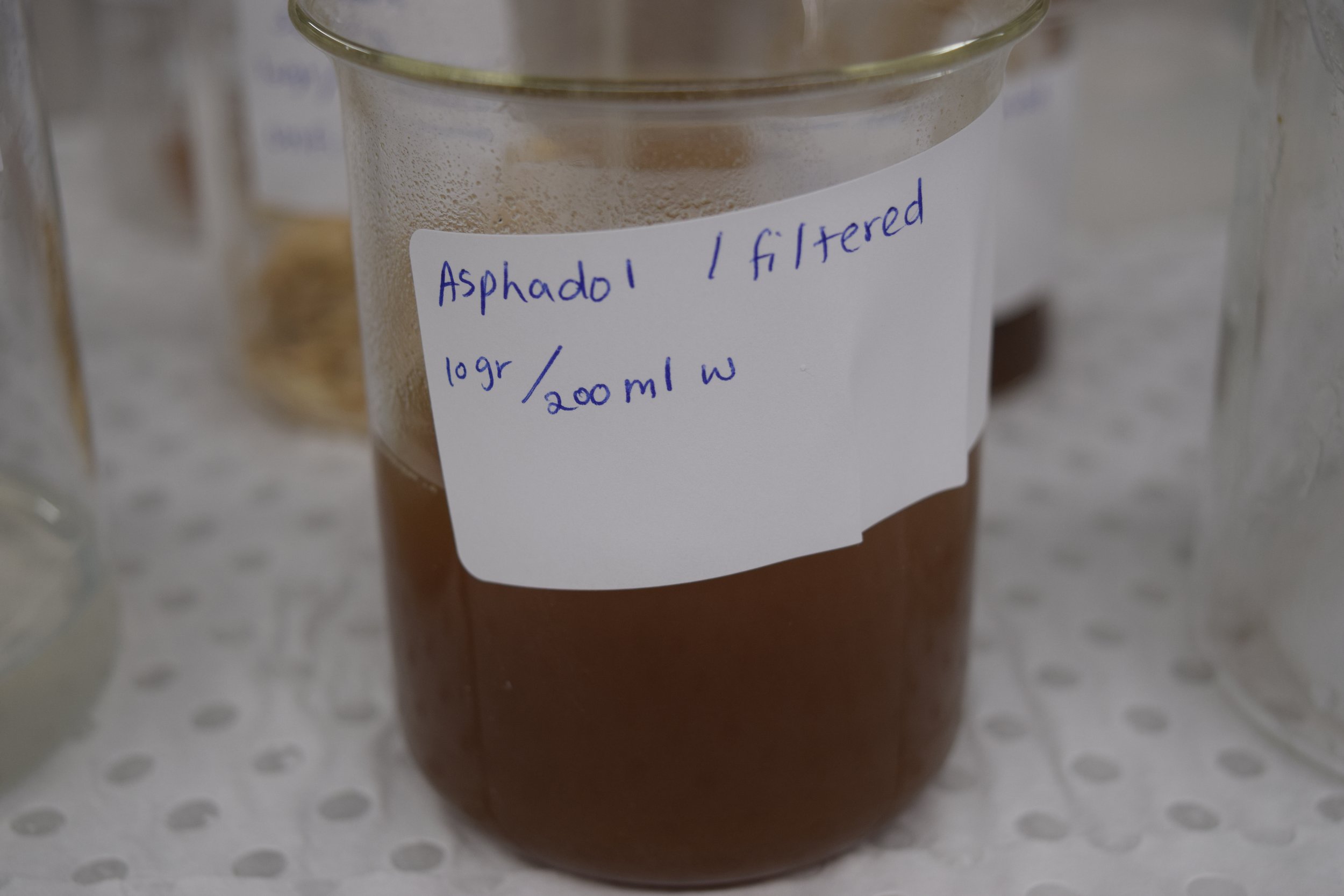

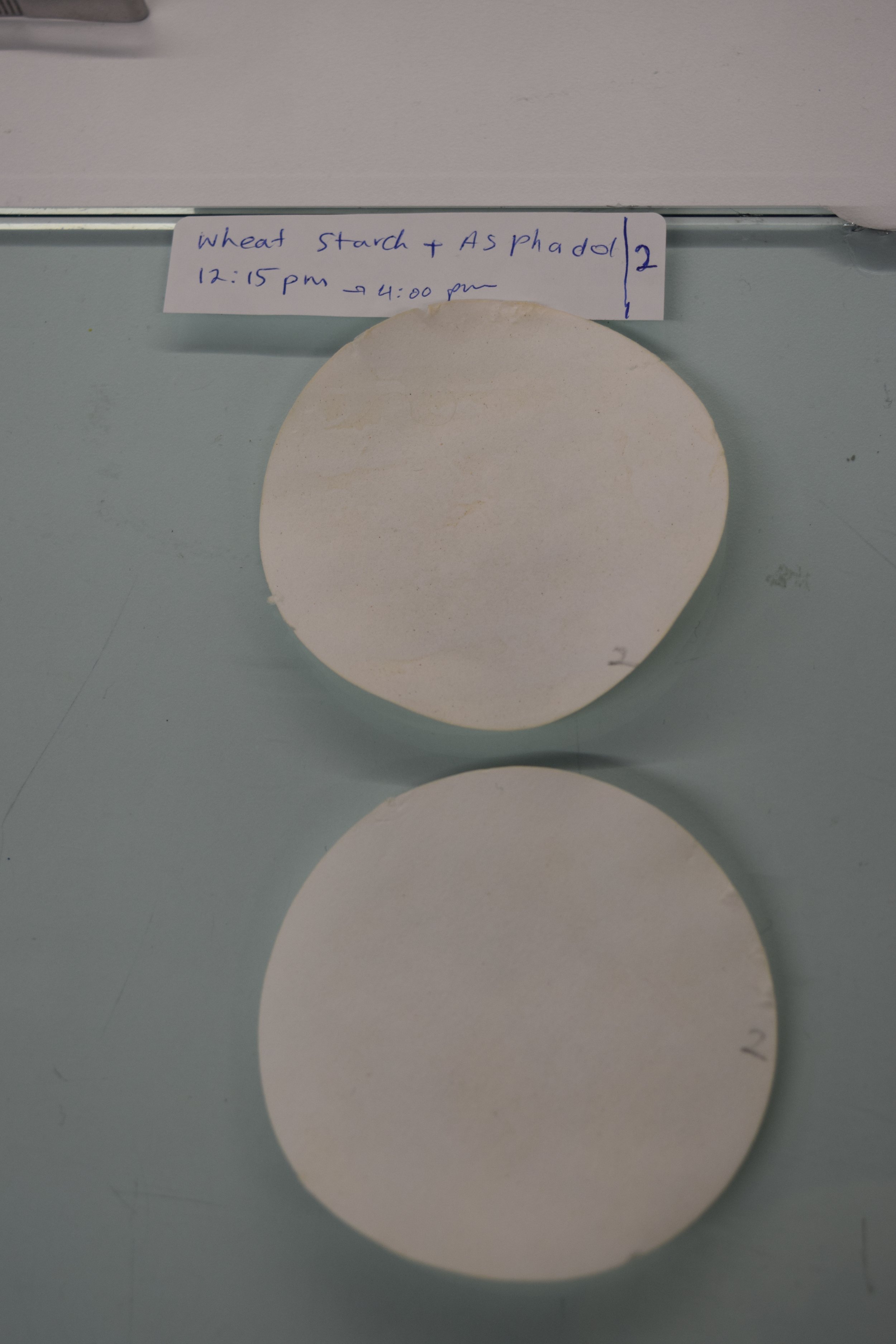

Pour 100ml of cold water into a glass jar with a 25g starch ratio of 1:4. Cover and soak the starch at room temperature for an hour. Transfer the mixture to a saucepan and cook over moderate heat, continually stirring. Meanwhile, heat 150ml of water in another saucepan, and just before it starts boiling, pour it slowly into the saucepan with the starch/water mixture, stirring the paste vigorously. Adding pre-heated water hastens the cooking process. More hot water can be added to reach the desired thickness. Cook for 35 minutes, stirring constantly with a wooden stick until obtaining a smooth paste. Remove the paste from the heat and let it cool.

Meanwhile, put 10g of seriš in a glass jar and pour in 100ml of cold water in a ratio of 1:10. Cover and soak. Then filter the extract and add it to the starch paste to thin the paste. Stir and strain the paste to obtain a smooth consistency, not too thick and not too thin. Moisten the paper and apply the paste on the paper with a brush or cotton balls. Hang the paper to dry. After it is completely dried, burnish it with a burnishing tool to smoothen the surface. Then burish the paper to achieve a smooth surface after the paper is dried.